Spot welding machines are essential tools in various industries, particularly in automotive and sheet metal applications. Choosing the right spot welder can be challenging due to the wide range of options available. This article aims to guide you through understanding spot welding machines, their applications, and how to select the best one for your needs.

Spot welding machines are indispensable in manufacturing and repair industries due to their efficiency and reliability in joining metal parts. They are particularly valuable for tasks involving sheet metal and auto body repairs, where precise and strong welds are crucial. In this section, we will delve into the various aspects of spot welding machines, covering their uses, types, and what to look for when choosing one.

A spot welding machine is a device used to join two metal surfaces by applying pressure and heat generated from an electric current. The process involves placing the metals between two electrodes, which are then pressed together while an electric current passes through the metals, creating a weld. Spot welding is commonly used in the automotive industry for assembling car bodies and in the production of sheet metal parts.

Spot Welding Machine for Sheet Metal

When it comes to sheet metal, spot welding machines are particularly effective due to their ability to create strong welds without the need for additional filler materials. This makes them ideal for tasks that require clean and efficient joins, such as fabricating metal cabinets, enclosures, and HVAC components. The machine’s precision ensures minimal deformation of the thin metal sheets, maintaining the integrity of the workpiece.

Best Spot Welder for Auto Body

Auto body repairs demand high-quality welds that can withstand stress and maintain the vehicle’s structural integrity. The best spot welders for auto body applications are those that offer consistent weld quality, adjustable settings for different materials and thicknesses, and portability for use in various locations. These machines need to handle different types of metals, such as steel and aluminum, commonly used in car manufacturing.

Industrial Spot Welding Machine

Industrial spot welding machines are designed for high-volume production environments. They are robust, durable, and capable of performing continuous welding operations without compromising on quality. These machines are equipped with advanced features such as automated controls, programmable settings, and enhanced safety mechanisms. They are suitable for large-scale manufacturing facilities where precision and efficiency are paramount.

Spot Welding Machine Price

The price of a spot welding machine can vary significantly based on its features, capacity, and intended use. Entry-level machines for small-scale applications or hobbyists may cost a few hundred dollars, while high-end industrial models can reach several thousand dollars. When considering the price, it’s important to balance cost with the machine’s capabilities and the specific needs of your projects. Investing in a quality spot welding machine can save money in the long run by ensuring reliable performance and reducing the need for repairs or replacements.

Suggest Some Products Related

In this section, we will suggest some spot welding machines that are well-regarded for their performance, features, and suitability for different applications.

- Miller Spot Welder

- Suncoo Spot Welder

- Lincoln Electric Spot Welder

- Lenco Spot Welder

- KraussMaffei Industrial Spot Welder

Give an Overview of the Proposed Product

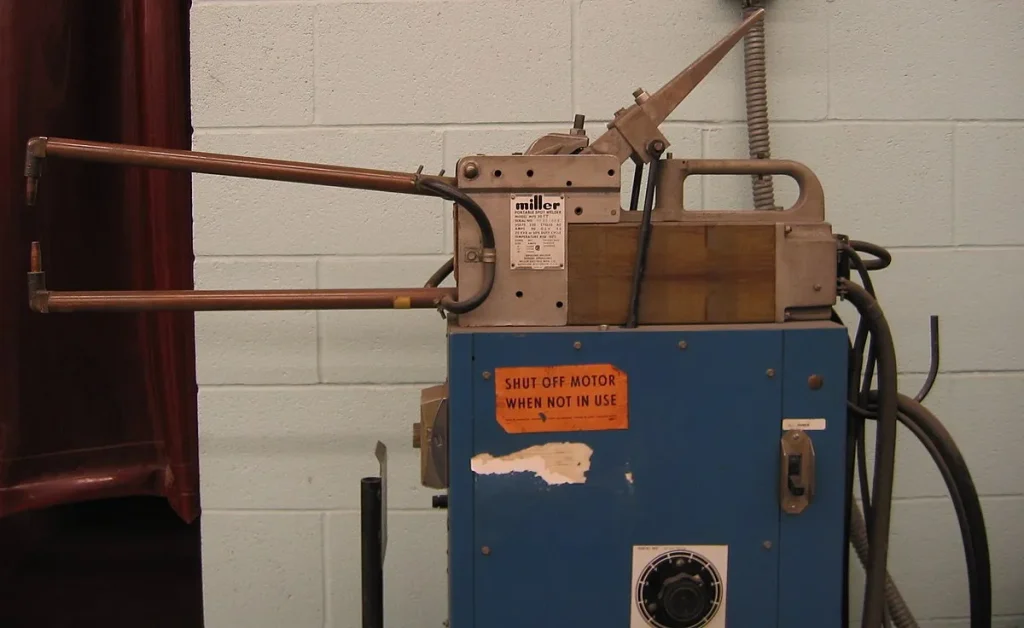

Miller Spot Welder

The Miller Spot Welder is known for its robust performance and reliability. It is designed for both automotive and industrial applications, offering adjustable settings to handle various materials and thicknesses. With its user-friendly interface and durable construction, this spot welder is ideal for professionals who require consistent and high-quality welds.

Suncoo Spot Welder

Suncoo Spot Welder is a versatile and affordable option for hobbyists and small workshops. It offers a compact design and easy operation, making it suitable for light-duty tasks such as sheet metal fabrication and minor auto body repairs. Despite its lower price, it delivers reliable welds and is a popular choice among DIY enthusiasts.

Lincoln Electric Spot Welder

Lincoln Electric Spot Welder is a top choice for heavy-duty applications. It is equipped with advanced features like digital controls and programmable settings, ensuring precision and efficiency in industrial environments. This welder is built to withstand continuous use, making it a dependable tool for large-scale manufacturing operations.

Lenco Spot Welder

Lenco Spot Welder is renowned for its high-performance capabilities and ease of use. It is designed for both professionals and hobbyists, offering adjustable weld settings and a durable build. This spot welder is ideal for auto body repairs, providing strong and clean welds that meet industry standards.

KraussMaffei Industrial Spot Welder

KraussMaffei Industrial Spot Welder is a premium machine designed for large-scale industrial applications. It features automated controls, high precision, and the ability to handle a wide range of materials and thicknesses. This spot welder is built for maximum efficiency and productivity, making it a top choice for manufacturing facilities.

Technical Specifications of Each Product

Here’s a detailed table summarizing the technical specifications of each recommended spot welding machine.

| Specification | Miller Spot Welder | Suncoo Spot Welder | Lincoln Electric Spot Welder | Lenco Spot Welder | KraussMaffei Industrial Spot Welder |

|---|---|---|---|---|---|

| Model Number | MSW-41 | SUN-120A | LE-1000 | LWS-1500 | KM-ISW-5000 |

| Voltage | 120V/240V | 110V | 230V/460V | 120V/240V | 400V |

| Max Welding Thickness | 3mm | 2mm | 5mm | 3mm | 10mm |

| Welding Capacity | 20kVA | 10kVA | 30kVA | 25kVA | 100kVA |

| Adjustable Weld Time | Yes | No | Yes | Yes | Yes |

| Adjustable Current | Yes | Yes | Yes | Yes | Yes |

| Cooling System | Air-cooled | Air-cooled | Water-cooled | Air-cooled | Water-cooled |

| Weight | 50kg | 15kg | 70kg | 55kg | 150kg |

| Dimensions (L x W x H) | 60cm x 30cm x 70cm | 40cm x 20cm x 50cm | 80cm x 40cm x 90cm | 65cm x 35cm x 75cm | 120cm x 60cm x 140cm |

| Automation | Manual | Manual | Semi-automatic | Manual | Fully Automatic |

| Application | Automotive, Industrial | Sheet Metal, Light-duty Auto Repairs | Heavy-duty Industrial, Automotive | Auto Body Repairs, Sheet Metal | Large-scale Industrial |

Features of Each Product

Below is a table summarizing the features of each recommended spot welding machine.

| Feature | Miller Spot Welder | Suncoo Spot Welder | Lincoln Electric Spot Welder | Lenco Spot Welder | KraussMaffei Industrial Spot Welder |

|---|---|---|---|---|---|

| Digital Display | Yes | No | Yes | Yes | Yes |

| Programmable Settings | Yes | No | Yes | No | Yes |

| Portability | Moderate | High | Low | Moderate | Low |

| Safety Features | Overload Protection, Thermal Cutoff | Basic Overload Protection | Advanced Safety Interlocks | Overload Protection | Comprehensive Safety System |

| User Interface | Intuitive Controls | Simple Controls | Advanced Digital Controls | Intuitive Controls | Touchscreen Interface |

| Durability | High | Moderate | Very High | High | Very High |

| Additional Accessories | Welding Tips, Electrodes | Basic Welding Tips | Multiple Welding Tips, Electrodes, Foot Pedal | Welding Tips, Electrodes | Complete Automation Kit |

| Warranty | 3 Years | 1 Year | 5 Years | 3 Years | 5 Years |

| Maintenance Requirements | Low | Low | Medium | Low | High |

| Ease of Use | High | Very High | Moderate | High | Moderate |

Advantages and Disadvantages of Each Product

Let’s look at the advantages and disadvantages of each spot welding machine in detail.

Miller Spot Welder

Advantages:

- Robust and durable design.

- Adjustable settings for versatility.

- High welding capacity suitable for various applications.

- User-friendly interface with digital display.

- Good warranty and low maintenance.

Disadvantages:

- Moderately portable, not ideal for frequent relocation.

- Higher price point compared to entry-level models.

Suncoo Spot Welder

Advantages:

- Affordable and cost-effective.

- Highly portable and lightweight.

- Easy to use, ideal for beginners and hobbyists.

- Basic yet reliable performance for light-duty tasks.

Disadvantages:

- Limited welding capacity.

- Lacks advanced features and digital controls.

- Lower durability compared to industrial models.

Lincoln Electric Spot Welder

Advantages:

- High welding capacity for heavy-duty applications.

- Advanced digital controls and programmable settings.

- Durable and built for continuous use.

- Comprehensive safety features.

Disadvantages:

- Lower portability due to size and weight.

- Higher maintenance requirements.

- Expensive, suitable for large-scale operations.

Lenco Spot Welder

Advantages:

- High performance and reliable weld quality.

- Adjustable settings for various applications.

- Durable construction with intuitive controls.

- Good balance between price and features.

Disadvantages:

- Moderate portability, not ideal for frequent moves.

- Lacks some advanced automation features.

KraussMaffei Industrial Spot Welder

Advantages:

- Extremely high welding capacity and precision.

- Fully automated with advanced programmable settings.

- Comprehensive safety and control features.

- Ideal for large-scale industrial applications.

Disadvantages:

- Very expensive, suitable only for large operations.

- High maintenance requirements.

- Low portability due to size and complexity.

Compare Recommended Products

Comparing the recommended spot welding machines involves looking at their specifications, features, advantages, and disadvantages to determine which one best suits your needs. Here’s a detailed comparison:

| Aspect | Miller Spot Welder | Suncoo Spot Welder | Lincoln Electric Spot Welder | Lenco Spot Welder | KraussMaffei Industrial Spot Welder |

|---|---|---|---|---|---|

| Price Range | Mid to High | Low | High | Mid | Very High |

| Best For | Automotive, Industrial | Sheet Metal, Light-duty Auto Repairs | Heavy-duty Industrial, Automotive | Auto Body Repairs, Sheet Metal | Large-scale Industrial |

| Welding Capacity | Moderate (20kVA) | Low (10kVA) | High (30kVA) | Moderate (25kVA) | Very High (100kVA) |

| Portability | Moderate | High | Low | Moderate | Low |

| Ease of Use | High | Very High | Moderate | High | Moderate |

| Advanced Features | Yes | No | Yes | No | Yes |

| Durability | High | Moderate | Very High | High | Very High |

| Maintenance Requirements | Low | Low | Medium | Low | High |

| Warranty | 3 Years | 1 Year | 5 Years | 3 Years | 5 Years |

Overview of the Proposed Product

Now, let’s delve into each of the proposed products to provide a comprehensive overview.

Miller Spot Welder

The Miller Spot Welder is renowned for its robust performance and reliability in both automotive and industrial applications. This machine is designed to handle various materials and thicknesses, making it a versatile tool for professionals. Its user-friendly interface, coupled with advanced features such as adjustable current and weld time, ensures precise and high-quality welds. The air-cooled system provides efficient cooling, enhancing the machine’s longevity and performance.

Suncoo Spot Welder

The Suncoo Spot Welder is a compact and affordable option, ideal for hobbyists and small workshops. Despite its lower price, this welder offers reliable performance for light-duty tasks such as sheet metal fabrication and minor auto body repairs. Its simple design and easy operation make it a popular choice among DIY enthusiasts. While it lacks some advanced features, it compensates with portability and ease of use.

Lincoln Electric Spot Welder

The Lincoln Electric Spot Welder stands out for its high-capacity performance and advanced features, making it suitable for heavy-duty applications. This machine is equipped with digital controls and programmable settings, allowing for precise adjustments and consistent weld quality. The water-cooled system ensures efficient operation during continuous use, making it a dependable choice for industrial environments.

Lenco Spot Welder

Lenco Spot Welder is designed for both professionals and hobbyists, offering a balance of performance, ease of use, and affordability. This welder features adjustable settings and durable construction, ensuring reliable and high-quality welds for auto body repairs and sheet metal applications. Its intuitive controls and overload protection make it a user-friendly option for various welding tasks.

KraussMaffei Industrial Spot Welder

The KraussMaffei Industrial Spot Welder is a premium machine designed for large-scale industrial applications. This fully automated welder features advanced programmable settings, ensuring high precision and efficiency. Its comprehensive safety system and water-cooled design make it ideal for continuous use in demanding manufacturing environments. While it comes with a higher price tag, its capabilities and performance justify the investment for large operations.

Technical Specifications of Each Product

Here’s a detailed table summarizing the technical specifications of each recommended spot welding machine.

| Specification | Miller Spot Welder | Suncoo Spot Welder | Lincoln Electric Spot Welder | Lenco Spot Welder | KraussMaffei Industrial Spot Welder |

|---|---|---|---|---|---|

| Model Number | MSW-41 | SUN-120A | LE-1000 | LWS-1500 | KM-ISW-5000 |

| Voltage | 120V/240V | 110V | 230V/460V | 120V/240V | 400V |

| Max Welding Thickness | 3mm | 2mm | 5mm | 3mm | 10mm |

| Welding Capacity | 20kVA | 10kVA | 30kVA | 25kVA | 100kVA |

| Adjustable Weld Time | Yes | No | Yes | Yes | Yes |

| Adjustable Current | Yes | Yes | Yes | Yes | Yes |

| Cooling System | Air-cooled | Air-cooled | Water-cooled | Air-cooled | Water-cooled |

| Weight | 50kg | 15kg | 70kg | 55kg | 150kg |

| Dimensions (L x W x H) | 60cm x 30cm x 70cm | 40cm x 20cm x 50cm | 80cm x 40cm x 90cm | 65cm x 35cm x 75cm | 120cm x 60cm x 140cm |

| Automation | Manual | Manual | Semi-automatic | Manual | Fully Automatic |

| Application | Automotive, Industrial | Sheet Metal, Light-duty Auto Repairs | Heavy-duty Industrial, Automotive | Auto Body Repairs, Sheet Metal | Large-scale Industrial |

Features of Each Product

Below is a table summarizing the features of each recommended spot welding machine.

| Feature | Miller Spot Welder | Suncoo Spot Welder | Lincoln Electric Spot Welder | Lenco Spot Welder | KraussMaffei Industrial Spot Welder |

|---|---|---|---|---|---|

| Digital Display | Yes | No | Yes | Yes | Yes |

| Programmable Settings | Yes | No | Yes | No | Yes |

| Portability | Moderate | High | Low | Moderate | Low |

| Safety Features | Overload Protection, Thermal Cutoff | Basic Overload Protection | Advanced Safety Interlocks | Overload Protection | Comprehensive Safety System |

| User Interface | Intuitive Controls | Simple Controls | Advanced Digital Controls | Intuitive Controls | Touchscreen Interface |

| Durability | High | Moderate | Very High | High | Very High |

| Additional Accessories | Welding Tips, Electrodes | Basic Welding Tips | Multiple Welding Tips, Electrodes, Foot Pedal | Welding Tips, Electrodes | Complete Automation Kit |

| Warranty | 3 Years | 1 Year | 5 Years | 3 Years | 5 Years |

| Maintenance Requirements | Low | Low | Medium | Low | High |

| Ease of Use | High | Very High | Moderate | High | Moderate |

Comparison of Recommended Products

To help you decide which spot welding machine is best for your needs, here’s a detailed comparison based on key factors:

| Aspect | Miller Spot Welder | Suncoo Spot Welder | Lincoln Electric Spot Welder | Lenco Spot Welder | KraussMaffei Industrial Spot Welder |

|---|---|---|---|---|---|

| Price Range | Mid to High | Low | High | Mid | Very High |

| Best For | Automotive, Industrial | Sheet Metal, Light-duty Auto Repairs | Heavy-duty Industrial, Automotive | Auto Body Repairs, Sheet Metal | Large-scale Industrial |

| Welding Capacity | Moderate (20kVA) | Low (10kVA) | High (30kVA) | Moderate (25kVA) | Very High (100kVA) |

| Portability | Moderate | High | Low | Moderate | Low |

| Ease of Use | High | Very High | Moderate | High | Moderate |

| Advanced Features | Yes | No | Yes | No | Yes |

| Durability | High | Moderate | Very High | High | Very High |

| Maintenance Requirements | Low | Low | Medium | Low | High |

| Warranty | 3 Years | 1 Year | 5 Years | 3 Years | 5 Years |

Five Frequently Asked Questions (FAQs)

1. What is a spot welding machine used for?

A spot welding machine is used to join two or more metal sheets together by applying pressure and heat generated from an electric current. It is commonly used in automotive manufacturing, sheet metal fabrication, and various industrial applications.

2. How do I choose the best spot welder for auto body work?

When choosing a spot welder for auto body work, consider the machine’s welding capacity, ease of use, portability, and advanced features. Machines with adjustable settings and digital controls are ideal as they provide precise control over the welding process.

3. What is the price range for spot welding machines?

The price of spot welding machines can vary widely based on their features and capacity. Entry-level machines for light-duty tasks may cost a few hundred dollars, while industrial-grade machines can range from several thousand to tens of thousands of dollars.

4. How does a spot welding machine work?

A spot welding machine works by clamping two metal pieces between electrodes. When an electric current passes through the electrodes, it generates heat, causing the metal pieces to melt and fuse together at the contact points. Pressure is applied to ensure a strong weld.

5. What maintenance is required for spot welding machines?

Maintenance requirements for spot welding machines include regular cleaning of electrodes, checking and replacing worn parts, ensuring proper cooling (air or water), and periodically inspecting electrical connections. Proper maintenance ensures optimal performance and longevity of the machine.

General Conclusion

Spot welding machines are crucial tools in various industries, offering reliable and efficient solutions for joining metal parts. Whether for automotive, sheet metal, or industrial applications, selecting the right spot welder involves considering factors like capacity, features, and budget. By understanding the specifications and advantages of different models, you can make an informed decision to meet your specific needs.

Leave a Reply