Welding technology is an essential component of modern industry, serving as the foundation for a vast array of manufacturing, construction, and repair processes. It’s a skill that has been honed over centuries, evolving from simple forge welding to sophisticated methods that use advanced machinery and materials. The ability to join metals together has given rise to innovations in architecture, transportation, and even space exploration. Among the tools that make this possible is the Harbor Freight Spot Welder—a testament to the progress in welding technology that combines efficiency with ease of use.

Technical Features of the Harbor Freight Spot Welder

The Harbor Freight Spot Welder is designed with the user in mind, featuring a user-friendly interface and a robust construction that promises durability and reliability. Its compact size belies its powerful performance, making it an ideal choice for both workshop and on-site applications.

Design and Construction: The welder’s design is focused on providing a balance between a lightweight build and the structural integrity required for heavy-duty use. It features a handle for easy transportation, and its body is constructed from durable materials that can withstand the rigors of a demanding work environment.

Key Specifications:

- Power Output: The welder operates on a standard 120V/240V power supply, making it versatile for use in various settings without the need for special electrical arrangements.

- Amperage Range: It offers a wide range of amperage settings, allowing for precise control over the welding process to accommodate different types of metal and thicknesses.

Accessories Included:

- The spot welder comes with essential accessories that enhance its functionality. These include an electrode holder, grounding clamp, and a starter pack of electrodes—all designed to get you welding right out of the box.

Detailed Specifications of the Harbor Freight Spot Welder

Voltage Compatibility:

- The welder is designed to work with both 120V and 240V power sources, making it adaptable to various electrical systems without the need for converters.

Power and Performance:

- With a power output that’s suitable for spot welding a wide range of metals, the welder is both energy-efficient and powerful.

Size and Portability:

- The compact design ensures it is lightweight enough to be portable, yet sturdy enough to handle the demands of consistent use.

Included Accessories:

- It comes with a comprehensive set of accessories to get you started, including electrodes and clamps, ensuring you have all you need for immediate welding tasks.

Advantages and Disadvantages of the Harbor Freight Spot Welder

Advantages:

- Cost-Effective: The welder offers a great balance between price and performance, making it an economical choice for many users.

- User-Friendly: Its straightforward controls make it accessible to beginners, while its robust features satisfy the demands of more experienced welders.

- Warranty and Support: Harbor Freight provides a solid warranty and customer support, adding value to your purchase.

Disadvantages:

- Material Limitations: The welder may not be suitable for all types of materials, which is important to consider before purchase.

- Maintenance: To keep the welder in top condition, regular maintenance is required, which might be a consideration for some users.

Product Introduction and Review

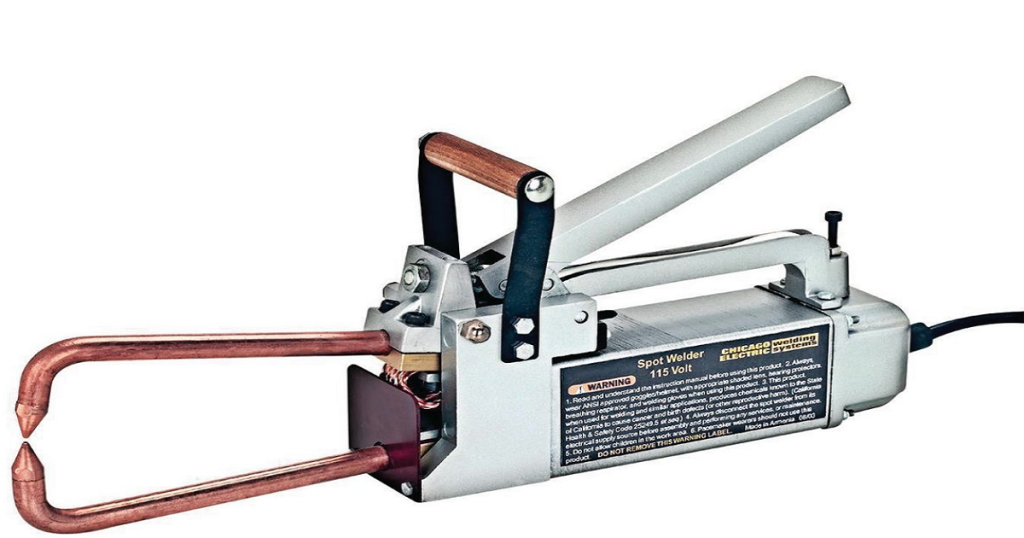

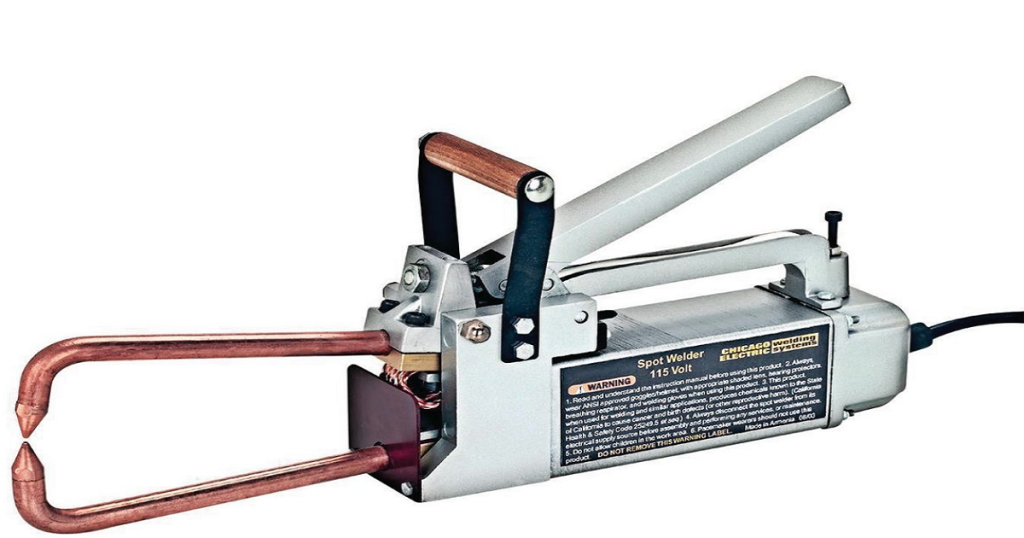

CHICAGO ELECTRIC 120V Spot Welder

- Introduction: This spot welder operates with a standard 120-volt household current and is designed to create strong welds quickly.

- Review: Users appreciate this machine for its quick welding capability and ease of use, but note that it is limited in capacity and lacks replacement welding tips at Harbor Freight.

- Advantages: Easy to use, affordable, suitable for household power sources.

- Disadvantages: Limited welding capacity, lack of replacement welding tips in the store.

CHICAGO ELECTRIC 240V Spot Welder

- Introduction: The 240V version provides additional power for heavier welding tasks, with compatibility with industrial power sources.

- Review: Manufacturers and professional welders value this machine for its ability to weld a variety of metals and its durability.

- Advantages: Powerful, suitable for industrial welding tasks, versatile in welding different materials.

- Disadvantages: Requires a 240V power source, more expensive than the 120V version.

CHICAGO ELECTRIC Stud Welder Dent Repair Kit

- Introduction: This kit includes a stud welder and the necessary accessories, making it easy to fix dents on car bodies without drilling.

- Review: It is considered a convenient and effective solution for bodywork repairs, especially for fixing small dents.

- Advantages: Convenient for car body repairs, no drilling required, easy to use.

- Disadvantages: May not be suitable for large dents or welding thicker metals.

Tips and Tricks for Using the Harbor Freight Spot Welder

Preparation:

- Proper preparation of materials and the setup of the machine are crucial for optimal welding results.

Safety Measures:

- Following safety guidelines is essential to prevent accidents and ensure a safe working environment.

Maintenance:

- Regular maintenance is key to prolonging the life of the welder and maintaining its performance.

Process Optimization:

- Applying certain tips can improve the quality of welds and reduce the time spent on each task.

Troubleshooting Common Issues

Identifying Problems:

- Understanding common issues and how to recognize them can prevent downtime and frustration.

Solving Issues:

- The welder is designed for easy troubleshooting, with straightforward solutions to common problems.

Conclusion

In summary, the Harbor Freight Spot Welder is a versatile and valuable tool for anyone involved in welding tasks. Its combination of affordability, ease of use, and reliable performance makes it a smart choice for both novices and seasoned professionals. With proper use and maintenance, it can be an excellent addition to any toolkit.

Leave a Reply