Electro fusion welding machines have revolutionized the way we join thermoplastic pipes and fittings, offering precise and reliable connections. These machines are widely used in various industries, including gas and water distribution, to ensure safe and efficient operations. In this article, we will delve into the details of electro fusion welding machines, exploring their specifications, features, and the best products available in the market.

Understanding the nuances of electro fusion welding machines can help professionals and hobbyists alike in making informed decisions about the equipment they need. This comprehensive guide aims to provide detailed insights into the functionality, technical specifications, advantages, and comparative analysis of leading electro fusion welding machines.

Article on “Electro Fusion Welding Machine”

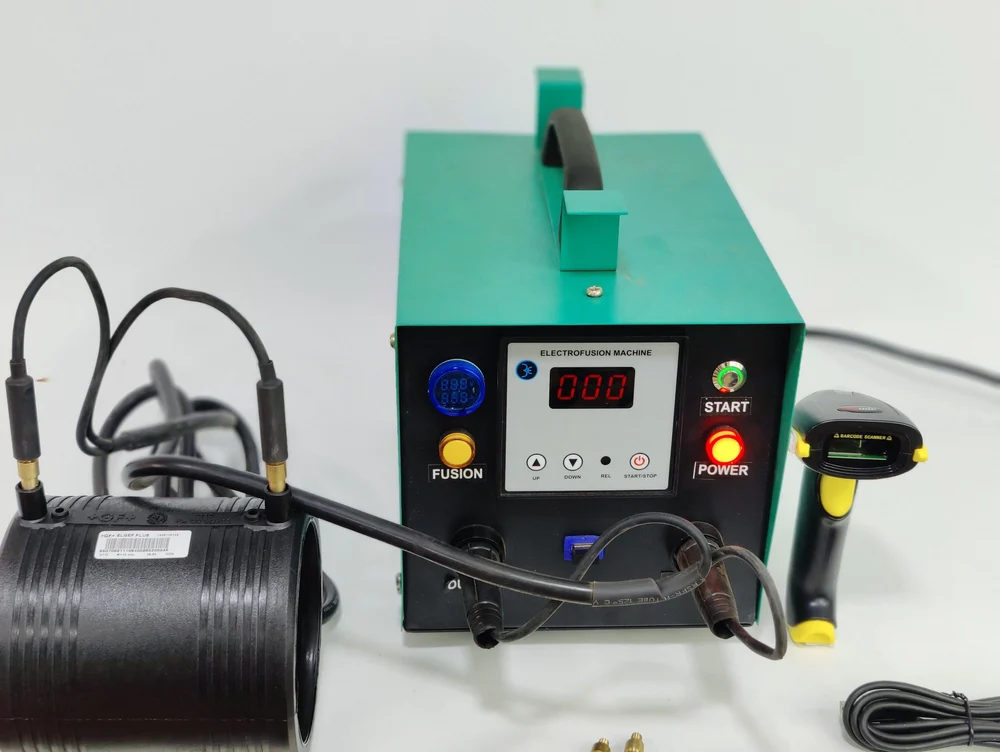

Electro fusion welding is a method used to join polyethylene (PE) pipes and fittings. This process involves using an electro fusion machine to pass an electrical current through a heating coil embedded in the fitting. The heat generated by the coil melts the PE material, creating a strong and permanent joint once it cools down. Electro fusion welding machines are essential tools in industries that require reliable and durable pipe connections, such as gas, water, and chemical distribution systems.

The primary advantage of electro fusion welding is its ability to create joints that are as strong as the pipe itself, ensuring leak-free and long-lasting connections. Moreover, the process is relatively straightforward and can be performed in various environmental conditions, making it highly versatile. This method also allows for the automation of welding processes, which can increase efficiency and reduce the risk of human error.

In addition to their practical benefits, electro fusion welding machines contribute to environmental sustainability by reducing the risk of leaks that could potentially contaminate soil and water sources. This is particularly important in industries such as gas and water distribution, where maintaining the integrity of the piping system is crucial.

Suggested Products Related to “Electro Fusion Welding Machine”

When selecting an electro fusion welding machine, it is crucial to consider the specific requirements of your project, including the pipe size, material, and environmental conditions. Here are some top products available in the market:

- Ritmo Elektra 500

- Fusion Group Easifuse

- Georg Fischer MSA 340

- Friatec Friamat Prime

These machines are renowned for their quality, reliability, and user-friendly features. They cater to a wide range of applications, making them suitable for both professional use and industrial applications. Below, we provide an overview of each of these recommended electro fusion welding machines.

Overview of the Proposed Products

Let’s take a closer look at each of these recommended electro fusion welding machines:

Ritmo Elektra 500

The Ritmo Elektra 500 is a versatile and reliable electro fusion welding machine designed for welding PE pipes and fittings. It is suitable for a wide range of applications, from gas and water distribution to industrial piping systems. This machine is known for its high welding efficiency and robust construction, making it a preferred choice for many professionals in the field.

Fusion Group Easifuse

The Fusion Group Easifuse machine offers advanced welding capabilities with user-friendly features, making it an ideal choice for both professional and occasional users. It is known for its robust construction and consistent performance. The Easifuse is designed to handle various pipe sizes, providing flexibility and adaptability in different project settings.

Georg Fischer MSA 340

The Georg Fischer MSA 340 is a high-performance welding machine designed for demanding applications. It features advanced technology and a durable design, ensuring precise and reliable welds in various conditions. This machine is particularly suitable for tough environments where precision and durability are paramount.

Friatec Friamat Prime

The Friatec Friamat Prime is a state-of-the-art electro fusion welding machine known for its ease of use and excellent performance. It is widely used in the gas and water distribution industries due to its reliability and efficiency. The Friamat Prime combines advanced technology with user-friendly features, making it a top choice for many professionals.

Technical Specifications of Each Product

| Product | Power Supply | Welding Range (mm) | Weight (kg) | Display Type | Data Logging |

|---|---|---|---|---|---|

| Ritmo Elektra 500 | 230V/50Hz | 20 – 500 | 19 | LCD | Yes |

| Fusion Group Easifuse | 230V/50Hz | 20 – 400 | 17 | LED | Yes |

| Georg Fischer MSA 340 | 230V/50Hz | 20 – 400 | 20 | LCD | Yes |

| Friatec Friamat Prime | 230V/50Hz | 20 – 500 | 18 | LCD | Yes |

The technical specifications of these machines highlight their capabilities and suitability for various welding tasks. The power supply for all the machines is standardized at 230V/50Hz, ensuring compatibility with most industrial power sources. The welding range varies, with the Ritmo Elektra 500 and Friatec Friamat Prime offering the widest range of 20-500mm, making them ideal for larger projects.

Features of Each Product

| Product | Key Features |

|---|---|

| Ritmo Elektra 500 | Easy-to-use interface, Robust design, High welding efficiency, Wide welding range, Built-in data logging |

| Fusion Group Easifuse | Compact design, User-friendly controls, Reliable performance, Suitable for various pipe sizes, Integrated data logging |

| Georg Fischer MSA 340 | Advanced technology, Durable construction, High precision, Suitable for tough environments, Comprehensive data logging |

| Friatec Friamat Prime | State-of-the-art technology, Ease of use, Reliable welding, Suitable for gas and water distribution, Extensive data logging |

Each of these electro fusion welding machines comes with a set of features that cater to different needs and preferences. The Ritmo Elektra 500 stands out with its high welding efficiency and user-friendly interface, making it suitable for a wide range of applications. The Fusion Group Easifuse is noted for its compact and portable design, which is ideal for on-site welding tasks.

Advantages and Disadvantages of Each Product

Ritmo Elektra 500

- Advantages: High welding efficiency, Wide range of applications, Durable design, User-friendly interface

- Disadvantages: Slightly heavier compared to some other models

The Ritmo Elektra 500 is highly efficient and versatile, making it suitable for a variety of welding tasks. However, its weight may be a drawback for those who require a more portable solution.

Fusion Group Easifuse

- Advantages: Compact and portable, Easy to operate, Consistent performance, Suitable for various pipe sizes

- Disadvantages: Lower welding range compared to some competitors

The Fusion Group Easifuse excels in portability and ease of use, making it ideal for on-site applications. Its lower welding range might be a limitation for larger projects.

Georg Fischer MSA 340

- Advantages: High precision welding, Durable and robust, Suitable for tough conditions, Comprehensive data logging

- Disadvantages: Heavier than some other models, More expensive

The Georg Fischer MSA 340 is known for its precision and durability, suitable for demanding environments. However, its weight and higher cost might be considerations for some users.

Friatec Friamat Prime

- Advantages: Excellent performance, Easy to use, Reliable welds, Extensive data logging

- Disadvantages: Slightly more expensive, Limited to certain pipe sizes

The Friatec Friamat Prime offers excellent performance and reliability, particularly in gas and water distribution systems. Its higher cost and size limitations may be factors to consider.

Comparison of Recommended Products

| Feature | Ritmo Elektra 500 | Fusion Group Easifuse | Georg Fischer MSA 340 | Friatec Friamat Prime |

|---|---|---|---|---|

| Power Supply | 230V/50Hz | 230V/50Hz | 230V/50Hz | 230V/50Hz |

| Welding Range (mm) | 20 – 500 | 20 – 400 | 20 – 400 | 20 – 500 |

| Weight (kg) | 19 | 17 | 20 | 18 |

| Display Type | LCD | LED | LCD | LCD |

| Data Logging | Yes | Yes | Yes | Yes |

| Key Features | High efficiency, Wide range, Durable, User-friendly | Compact, Portable, Reliable, User-friendly | High precision, Durable, Suitable for tough conditions | State-of-the-art, Reliable, Extensive data logging |

Comparing these products helps highlight their unique strengths and potential limitations. The Ritmo Elektra 500 and Friatec Friamat Prime offer the widest welding range, making them suitable for large-scale projects. The Fusion Group Easifuse, on the other hand, provides excellent portability and ease of use, which is ideal for on-site applications.

The Georg Fischer MSA 340 stands out with its high precision and durability, making it a reliable choice for demanding environments. While it may be heavier and more expensive, its comprehensive data logging and advanced technology make it a valuable investment for complex projects.

Frequently Asked Questions

Q1: What is an electro fusion welding machine?

A1: An electro fusion welding machine is a device used to join polyethylene (PE) pipes and fittings by using an electrical current to melt the material, creating a strong and permanent joint.

Q2: What are the benefits of using electro fusion welding?

A2: The benefits include creating joints that are as strong as the pipe itself, ensuring leak-free connections, and the ability to perform welds in various environmental conditions. Additionally, electro fusion welding machines reduce the risk of leaks that could contaminate soil and water sources.

Q3: How do I choose the right electro fusion welding machine?

A3: Consider factors such as the welding range, power supply, weight, display type, and data logging capabilities to choose the machine that best suits your project requirements. It is also important to consider the specific needs of your application, such as the size and type of pipes you will be working with.

Q4: What is the typical welding range for electro fusion machines?

A4: The welding range typically varies from 20mm to 500mm, depending on the machine model and manufacturer. Machines with a wider welding range offer greater flexibility and are suitable for a variety of projects.

Q5: Can electro fusion welding machines be used for both gas and water distribution?

A5: Yes, electro fusion welding machines are widely used in both gas and water distribution systems due to their reliability and strong welds. These machines are designed to handle the specific requirements of these industries, ensuring safe and efficient connections.

General Conclusion

Electro fusion welding machines are essential tools for creating reliable and durable pipe connections in various industries. By understanding the specifications, features, advantages, and disadvantages of different models, you can choose the best machine for your needs. Whether you are working in gas, water, or industrial piping systems, investing in a high-quality electro fusion welding machine will ensure safe and efficient operations. As technology continues to advance, these machines will likely become even more efficient and user-friendly, further enhancing their value in industrial applications.

Leave a Reply