In the world of industrial applications, precision and efficiency are paramount. This is where the Climax Bore Welder comes into play. Renowned for its high-quality performance, the Climax Bore Welder is a crucial tool for professionals seeking reliable welding solutions. This article will explore the top five benefits of using a Climax Bore Welder, highlighting its advantages over traditional welding methods and how it can revolutionize your industrial processes.

The Climax Bore Welder is specifically designed for applications that require meticulous attention to detail and robust welding capabilities. Whether you’re working in construction, machinery repair, or heavy equipment maintenance, understanding the benefits of this advanced welding tool can significantly impact your operations. From improving accuracy to enhancing productivity, the Climax Bore Welder offers solutions that address common challenges faced in industrial settings.

Benefit 1: Precision and Accuracy

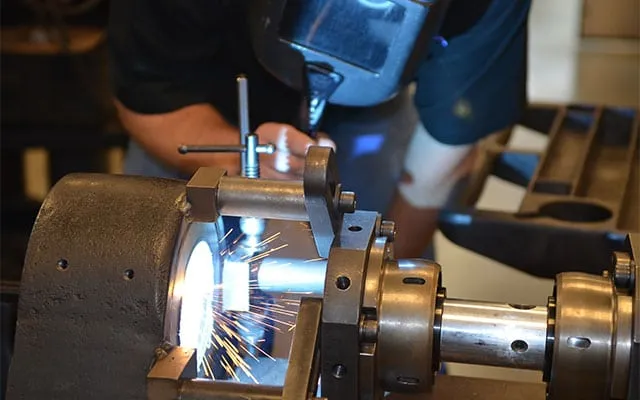

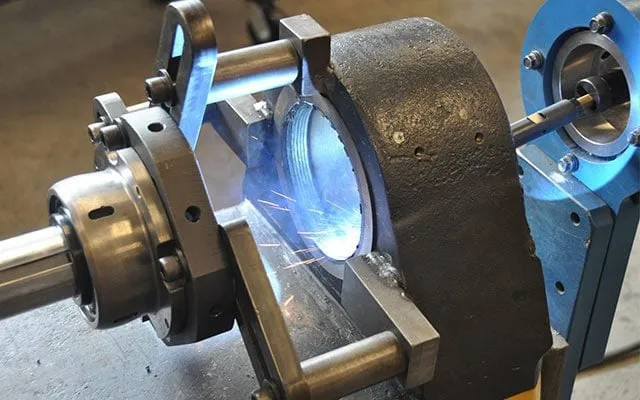

One of the standout features of the Climax Bore Welder is its exceptional precision and accuracy. In industrial settings where exact measurements and flawless welds are critical, this welder shines by delivering consistent results every time.

The Climax Bore Welder is engineered with advanced technology that allows for precise control over welding parameters. This includes adjustable settings for temperature, speed, and pressure, enabling operators to achieve the exact specifications required for each job. The ability to finely tune these parameters helps ensure that welds are uniform and meet stringent quality standards.

Application Examples:

- Equipment Repair: In industries where large machinery or structural components are repaired, precision welding is essential to restore the integrity of the equipment. The Climax Bore Welder’s ability to perform high-precision welds makes it ideal for repairing critical components like hydraulic cylinders and rotating equipment.

- Custom Fabrication: For projects that require bespoke components with tight tolerances, such as aerospace or automotive parts, the Climax Bore Welder provides the accuracy needed to create custom pieces that fit perfectly and perform reliably.

By ensuring that every weld is executed with pinpoint accuracy, the Climax Bore Welder not only enhances the quality of work but also minimizes the need for rework and adjustments, ultimately leading to more efficient operations.

Benefit 2: Enhanced Efficiency and Productivity

Efficiency and productivity are key metrics in any industrial operation, and the Climax Bore Welder excels in both areas. Its design and features are tailored to streamline welding processes, making it a valuable asset for any workshop or job site.

The Climax Bore Welder is equipped with features that boost operational efficiency. For example, its quick setup and calibration capabilities allow operators to get up and running faster. The welder’s automated functions, such as preset welding programs and automatic adjustments, reduce the time spent on manual settings and allow for more consistent results.

Comparison: Compared to traditional welding methods, the Climax Bore Welder offers significant time savings. Traditional welders often require extensive setup and adjustments, which can lead to delays and increased labor costs. In contrast, the Climax Bore Welder’s user-friendly interface and automated features enable faster turnaround times for welding tasks.

Examples of Increased Productivity:

- Heavy Machinery: In industries dealing with large-scale machinery repairs, the Climax Bore Welder’s efficiency translates into quicker repairs and less downtime, allowing businesses to maintain their equipment and keep operations running smoothly.

- Mass Production: For manufacturing environments that require repetitive welding tasks, the welder’s ability to perform high-speed, accurate welds contributes to higher production rates and reduced cycle times.

Benefit 3: Cost Savings on Maintenance and Repairs

Investing in a high-quality tool like the Climax Bore Welder can lead to significant cost savings over time, particularly in maintenance and repair operations. This benefit is crucial for businesses looking to optimize their budget and enhance their financial efficiency.

The Climax Bore Welder is designed for durability and reliability, which translates to lower maintenance costs. Its robust construction and high-quality components reduce the likelihood of breakdowns and the need for frequent repairs. Additionally, the welder’s efficient operation minimizes material waste and the need for rework.

Cost Analysis:

- Initial Investment vs. Long-Term Savings: While the upfront cost of a Climax Bore Welder may be higher compared to cheaper alternatives, the long-term savings on maintenance and repairs often justify the investment. Fewer breakdowns and repairs mean lower operational costs and less disruption to production.

- Reduced Material Waste: The precision of the Climax Bore Welder ensures that materials are used efficiently, reducing waste and the associated costs of purchasing and handling additional materials.

Examples of Cost Savings:

- Industrial Maintenance: For businesses involved in maintaining and repairing large equipment or infrastructure, the reduced need for repairs and the efficiency of the Climax Bore Welder can lead to significant savings in labor and material costs.

- Repair Shops: Workshops that handle a high volume of repair work can benefit from the Climax Bore Welder’s reliability, which helps in maintaining a steady workflow and avoiding costly delays.

By providing reliable performance and reducing maintenance needs, the Climax Bore Welder helps businesses manage their budgets more effectively and achieve better cost control.

Benefit 4: Versatility in Industrial Applications

The Climax Bore Welder stands out for its versatility, making it a valuable tool across a wide range of industrial applications. Its adaptability to various tasks and environments enhances its utility and makes it an asset in diverse industrial settings.

The Climax Bore Welder is designed to handle a variety of welding tasks with ease. Its adjustable settings and specialized features enable it to work with different materials and welding processes. Whether you need to weld thin metal sheets or thick structural components, this welder is equipped to meet the challenge.

Examples of Versatility:

- Construction: In the construction industry, the Climax Bore Welder can be used for welding steel beams, reinforcing structures, and repairing construction equipment. Its ability to perform precise and strong welds ensures the integrity of construction projects.

- Manufacturing: For manufacturing applications, the welder can be used in the production of machinery parts, custom components, and assembly of metal structures. Its flexibility allows it to adapt to various production needs, improving overall efficiency.

- Shipbuilding: In shipbuilding, where large and complex metal structures are common, the Climax Bore Welder provides the necessary power and precision to handle challenging welding tasks, ensuring the durability and safety of maritime vessels.

Advantages of Versatility:

- Reduced Need for Multiple Tools: The Climax Bore Welder’s ability to handle different welding tasks reduces the need for multiple specialized tools, saving space and reducing equipment costs.

- Enhanced Capability: Its versatility allows businesses to expand their range of services and tackle a broader array of projects, increasing their competitiveness in the market.

By offering adaptability across various industrial applications, the Climax Bore Welder helps businesses achieve greater flexibility and efficiency in their operations.

Conclusion

In conclusion, the Climax Bore Welder is a game-changing tool for industrial applications, offering a range of benefits that enhance precision, efficiency, and cost-effectiveness. From its ability to deliver highly accurate welds to its role in improving productivity and reducing maintenance costs, this welder proves to be a valuable asset in any industrial setting.

Summary of Benefits:

- Precision and Accuracy: Ensures flawless welds and meets stringent quality standards.

- Enhanced Efficiency and Productivity: Streamlines welding processes and boosts operational performance.

- Cost Savings on Maintenance and Repairs: Reduces long-term costs through durable performance and efficient operation.

- Versatility in Industrial Applications: Adapts to a wide range of tasks and materials, offering flexibility and expanded capabilities.

Leave a Reply